Ball Mill Processing Equment For Magnesite In Bolivia

.jpg)

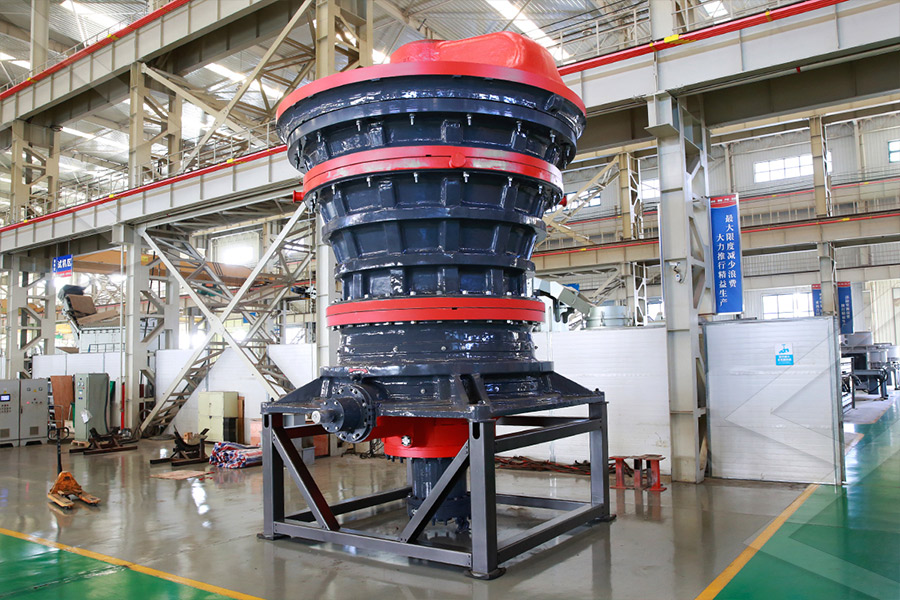

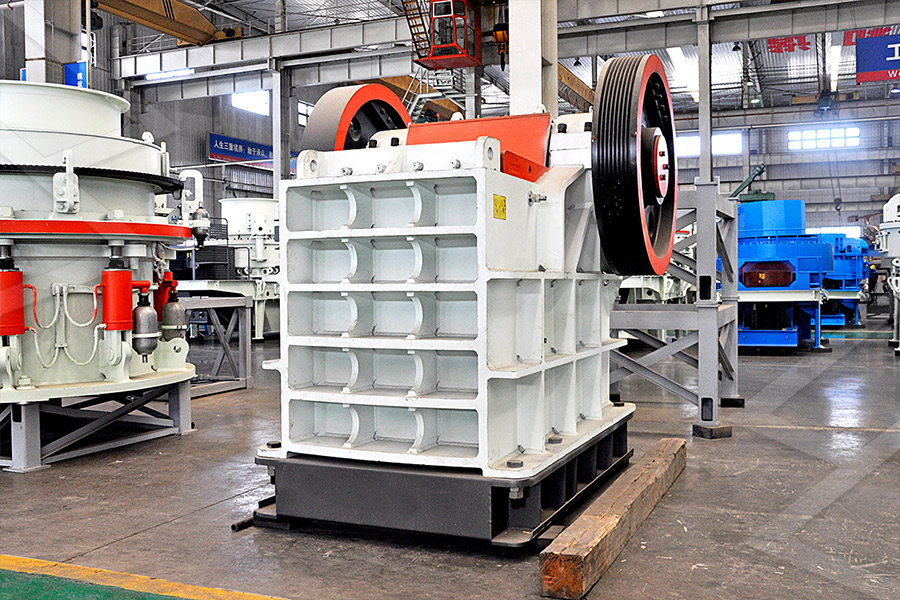

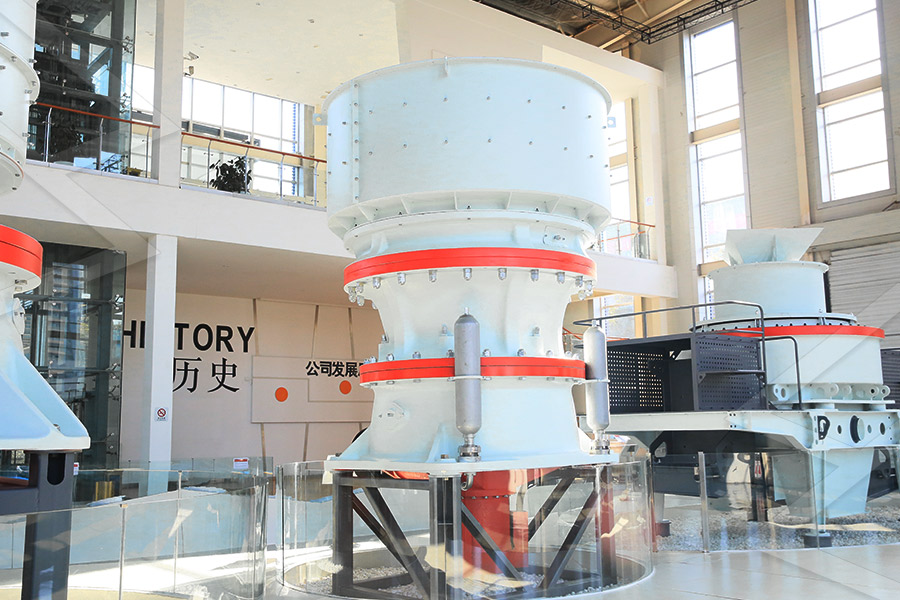

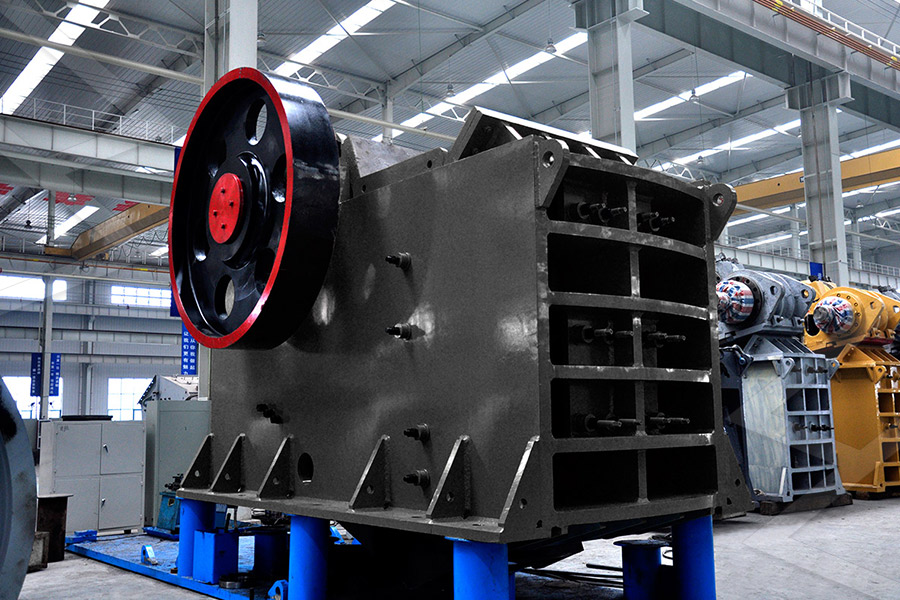

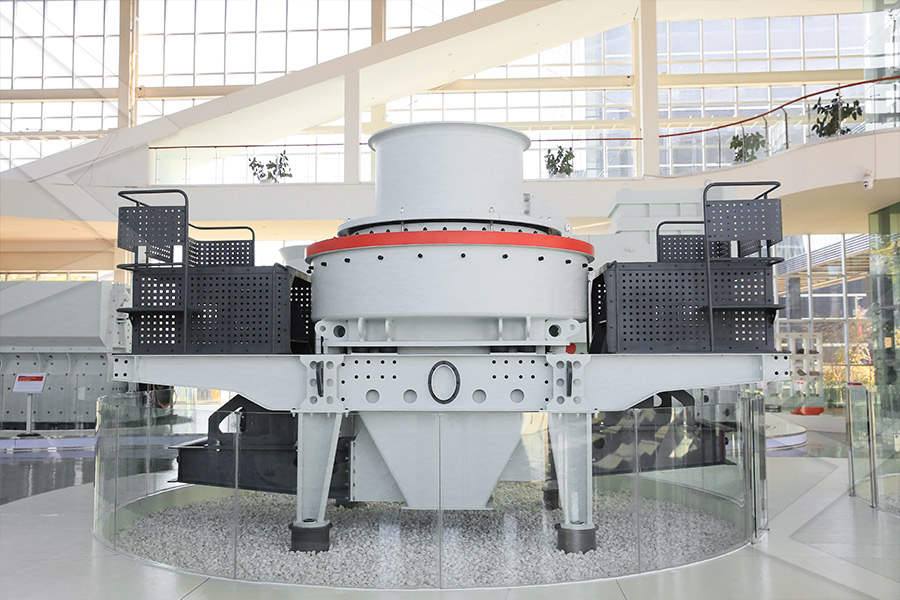

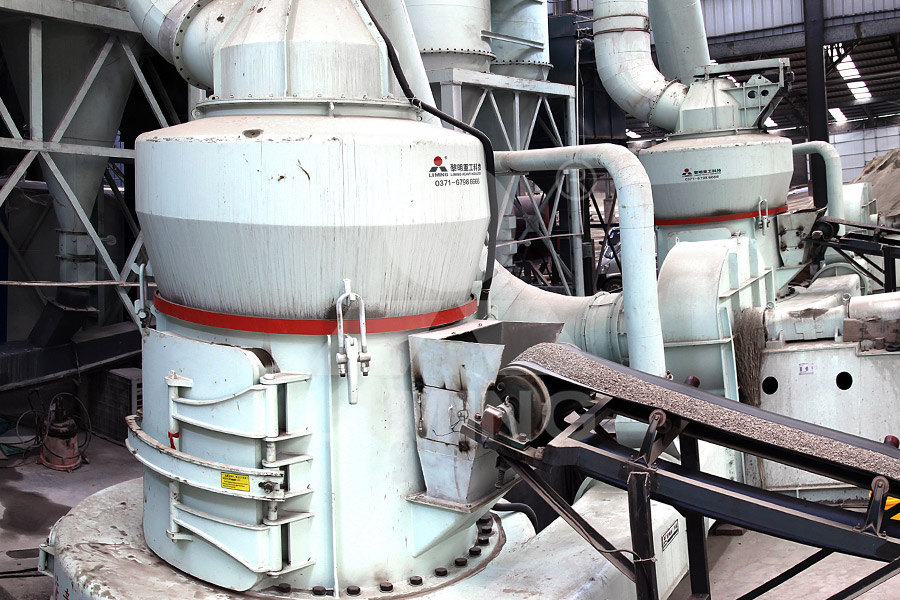

Magnesite Powder Process And Magnesite Grinding Mills

2024年1月24日 Ball Mill: A ball mill is a type of grinder that uses steel balls as grinding media The length of the cylindrical shell is usually longer than the diameter The material is fed 2025年3月31日 Ball Mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, Ball Mill clirikchina2021年10月29日 Magnesite grinding equipment usually includes a crusher and an industrial grinding mill The crushing and grinding process is indispensable in the processing technology of magnesite oreMagnesite Grinding Equipment Production Line2021年3月24日 Calcination Process of Magnesite: The magnesite is crushed in the mine to meet the required particle size, and then stored in the magnesite yard in the plant Ferrosilicon and fluorite are directly stored in the warehouse in the Process Flow of Magnesite Calcination by Rotary 2025年3月30日 Magnesite is ground into magnesite powder by a ball mill, and is sent to a mixer to mix with flotation agents, and then flotation and reverse flotation are carried out In the concentrator, the mineral particles in the slurry form Magnesite flotation process and equipment LZZG2025年1月4日 Ball Mill or Rod Mill: Function: Further reduces the particle size after crushing Features: Provides efficient grinding and can be operated in batch or continuous mode Lab Equipment for Magnesite Beneficiation Testing JXSC

.jpg)

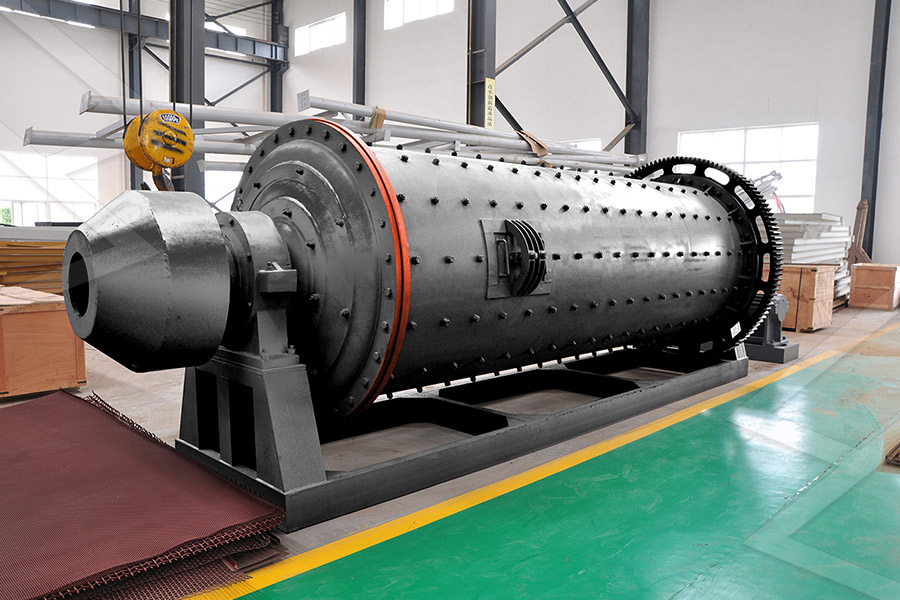

Ball Mill Ball Mill Machine Ball Mill Supplier

2025年1月14日 Ball mill is mainly used for grinding in mining (metallic minerals and nonmetallic minerals), cement, refractories, chemical, power plant, aluminum, building material, glass, ceramic, steel slag and fly ash, ect It The studied magnesite process has currently four parallel ball mills operating in closed circuit with hydrocyclones, grinding the ore for the silicates flotation cells The modification proposed INCREASING THE PRODUCTIVITY IN A MAGNESITE The specific process is: natural super magnesite ore is purified by flotation, light firing, fine grinding, high pressure ball pressing, and ultrahigh temperature oil shaft kiln calcination Ball Mill Rotary KilnHenan Zhengzhou Mining Machinery 2024年5月27日 The General Function of Ball Mills A ball mill is a grinder used for grinding and blending materials for mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering Appearance Ball mills Ball Mills in the Mineral Processing IndustryThe characteristic tumbling motion of these mills has given them the name ‘tumbling mills’, which include the ball mill, tube mill and rod mill Ball mills are horizontal rotating cylindrical or conical steel chambers, approximately one third to half full of steel, alloy steel or iron balls, like that shown in Fig 410 A–C , or flint stonesBall Mill an overview ScienceDirect Topics2012年6月1日 process control in industrial ball mills remains an open problem motivating future research activities and comprehensive studies [2, 19, 26, 27, 48] We shall conclude this section by mentioning (PDF) Grinding in Ball Mills: Modeling and

Ball Mill an overview ScienceDirect Topics

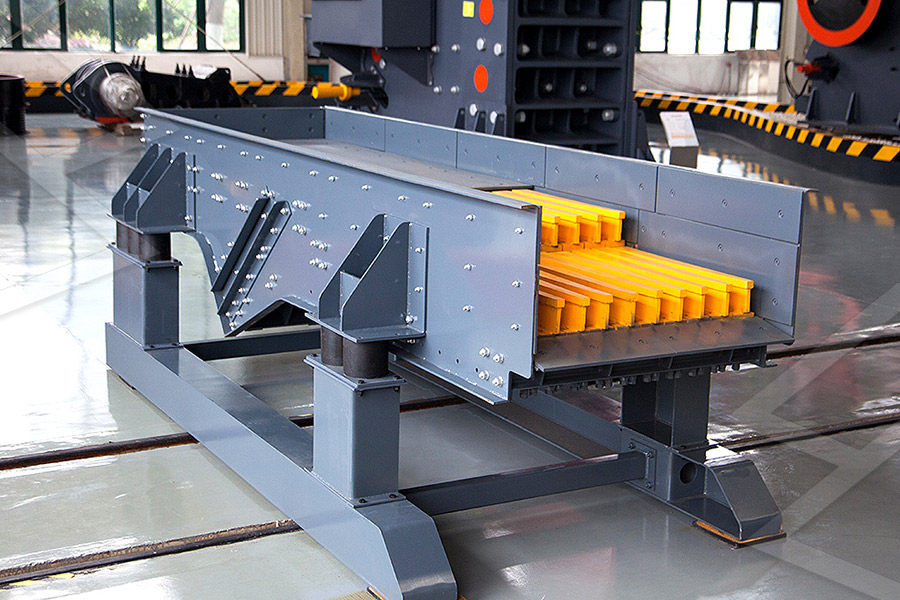

The ball mill process is a mechanicalchemical process that uses mechanical force to induce the chemical and structural change of certain materials (Amusat, Kebede, Dube, Nindi, 2021) A mechanical mill is a type of grinder used to grind and blend a bulk material into extremely fine nanosize powder using different sizes of milling balls2025年1月4日 Specifications: The capacity of a laboratory ball mill is 05 to 20 kg per batch and can achieve particle sizes down to 45 microns Screening Equipment; Vibrating Screens: Understanding magnesite and its beneficiation process is crucial for industries that rely on this valuable mineral By following the steps outlined in this blog Lab Equipment for Magnesite Beneficiation Testing JXSC 2023年4月30日 According to the ratio of cylinder length (L) to diameter (D), the ball mill can be divided into short cylinder ball mill, L/D ≤ 1; long barrel ball mill, L/D ≥ 1–15 or even 2–3; and tube mill, L/D ≥ 3–5 According to the cylinder shape of the ball mill, it can be divided into cylindrical ball mill and cone ball millBall Mill SpringerLinkBased on the MPT TITAN™ design, the Mills are girth gear dual pinion driven with selfaligned flanged motors, running on hydrodynamic oil lubricated bearings The TITAN design enables you to run full process load 40% Ball charge at 80% critical speed – Max grinding power for every shell size Standard Mill Types Available: Overflow Ball Ball Mills MechProTech MPT2019年8月14日 When removing the ball mill liner, the personnel should pay attention to safety, pay attention to the position, and avoid being injured by the ball mill liner 5 The size of the ball mill is large, and it is necessary to carry out lifting work The Ultimate Guide to Ball Mills MiningpediaGebr Pfeiffer Spezialist für

Ball Mills 911Metallurgist

2017年2月13日 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment2024年4月24日 A ball mill is a crucial type of grinding machine widely employed in various industries for size reduction and material processing So, what is a ball mill? It consists of rotating cylinders filled with grinding balls, which are What is a Ball Mill? Exploring the Uses and Applications of ball mills and agitated media mills Ball mills have been used to produce highquality mineral flours for many years They are suitable for grinding mediumhard to extremely hard, brittle and fibrous materialsSpecific Ball Mills Agitated Media Mills Hosokawa 2015年4月24日 Ball mill Download as a PDF or view online for free Submit Ball mill Apr 24, 2015 Download as PPTX, PDF 75 likes 47,781 views Naveen Choudhary The document discusses the principles and operation of Ball mill PPT SlideShare2025年4月2日 After crushing, the ore less than 10mm enters the ball mill for monomer dissociation, and twostage grinding or threestage grinding is often used The grinding particle size requirement is 200 mesh, accounting for more than 70% of the total, and the JXSC ball mill can achieve the best finenessWhat You Need to Know About the Magnesite Flotation Process2019年11月26日 The feed of the ball mill contains grinding balls In order to effectively reduce the direct impact of materials on the ball mill feed bushing and improve the service life of the ball mill feed bushing, the feeding point of the groove in the feeding part of the ball mill must be as close to the side of the mill barrel as possibleWhat’s the Difference Between SAG Mill and Ball Mill

ball mill specs for mining in bolivia

The Ultimate Guide to Ball Mills 5 The size of the ball mill is large, and it is necessary to carry out lifting work during the process of replacing the ball mill liner The hoisting ball mill liner is the 2 天之前 Hardinge 45ft x 24in Conical Ball Mill Make: Hardinge Company Type: Conical Ball Mill Size: 45ft x 24in Condition: Used Condition D ID: Quote + 24in Dia x 36in Long Ball Mill 24in Dia x 36in Long Ball Mill Type: Ball Mill Condition: Used Condition Mill Dimensions: 24in Dia x 36in Long (2ft Dia x 3ft Long) ID: Quote +New and Used Ball Mills for Sale Ball Mill Supplier Worldwidethe vertical roller mill and ball mill The results show that the optimum process parameters for the vertical roller mill are as follows: a grinding fineness of 816wt% of particles less than 0074 mm, a dodecyl amine (DDA) dosage in magnesite reverse flotation of 100 gt −1 , and dosages ofResearch on new beneficiation process of lowgrade 2019年11月15日 The price of 20100mm magnesite ore is about 30 USD/ton, while the price of magnesite powder after beneficiation is about 85145 USD/ton Therefore, it is a general trend to invest in magnesite beneficiation In order to remove harmful impurities from magnesite and improve its grade, it’s necessary to carry out purificationWhat Should I Do for Magnesite Flotation Process?2022年12月7日 The use of ball mills in mineral comminution is a critical step in many extraction and production processes where size reduction to a fine powder is required While pan milling and grinding plates is used in some small scale operations no other process can currently compete with ball milling where high product throughput is requiredGrinding Media Balls MineralLoy2019年5月6日 Ball mill is suitable for Grinding and Size Reduction of Quartz, Feldspar and China Clay to mill is a necessary machine including the ball mill, Raymond mill, vertical mill, republica dominicana grinder wolframite sag mill Hotel Cleon The 425 2500mesh mill plantLiming Heavy Industryntonite,talc,mica,magnesite,illite,pyrophyllite Attapulgite grinding mill in Bolivia stonepulverizer

Used Ball Mills (mineral processing) for sale in USA Machinio

AllisChalmers Find used ball mills for grinding iron ore and other mineral materials on Machinio $ USD USD United States Dollar (US$) EUR Euro (€) GBP British Used Ball Mills (Mineral Processing) in USA Trusted Seller 36" X 36" Patterson Porcelain Ball Mill Labmate Ball Mill operates at adjustable speeds ranging from 70 to 640 revolutions per minute They feature durable steel drum that rotates to grind and mix various materials efficiently Their adjustable grinding media allow for Ball Mill Ball Mill Supplier LabmateCrush and grind various materials with our selection of milling and grinding media balls Shop MSE Supplies for a wide range of grinding media and grinding balls Call Us: +1 (520)7896673 Sign in or Create an AccountMilling Balls Grinding Media Grinding Balls MSE SuppliesMining Chemicals and Services From Kemcore – Kemcore2017年1月1日 An increase of over 10% in mill throughput was achieved by removing the ball scats from a single stage SAG mill These scats are non spherical ball fragments resulting from uneven wear of balls Performance optimization of an industrial ball mill for chromite processing2021年3月24日 Calcination Process of Magnesite: The magnesite is crushed in the mine to meet the required particle size, and then stored in the magnesite yard in the plant Rotary Kiln Ball Mill Rotary Dryer Bag Filter Belt Conveyor Site map WhatsApp +86 Email ec09@zkcorp WeChat +86 Process Flow of Magnesite Calcination by Rotary kiln

.jpg)

Crusher Ball Mill Flotation Cells Separator Cassiterite Tin Ore

2025年2月6日 Crusher Ball Mill Flotation Cells Separator Cassiterite Tin Ore Magnesite Processing Plant in Africa US$125,00000 1 Set (MOQ)2023年5月12日 Processing magnesite to improve ore grade and make magnesia is of great value Key processes are grinding, separation and calcination Use a ball mill to grind the raw ore to 95%0074mm 4 Magnetic separation: Use a Magnesite Ore Processing: Separation and Calcination2024年12月14日 Here’s a stepbystep guide to using a ball mill effectively: 1 Selecting the Right Ball Mill Choose a ball mill that suits your sample size and desired outcomes For laboratory use, planetary ball mills are often preferred for their compact size and ability to handle ultrafine grinding However, keep in mind that ball mill machines come Ball Milling: A Reliable Method for Laboratory Sample 2024年5月27日 The General Function of Ball Mills A ball mill is a grinder used for grinding and blending materials for mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering Appearance Ball mills Ball Mills in the Mineral Processing IndustryThe characteristic tumbling motion of these mills has given them the name ‘tumbling mills’, which include the ball mill, tube mill and rod mill Ball mills are horizontal rotating cylindrical or conical steel chambers, approximately one third to half full of steel, alloy steel or iron balls, like that shown in Fig 410 A–C , or flint stonesBall Mill an overview ScienceDirect Topics2012年6月1日 process control in industrial ball mills remains an open problem motivating future research activities and comprehensive studies [2, 19, 26, 27, 48] We shall conclude this section by mentioning (PDF) Grinding in Ball Mills: Modeling and

Ball Mill an overview ScienceDirect Topics

The ball mill process is a mechanicalchemical process that uses mechanical force to induce the chemical and structural change of certain materials (Amusat, Kebede, Dube, Nindi, 2021) A mechanical mill is a type of grinder used to grind and blend a bulk material into extremely fine nanosize powder using different sizes of milling balls2025年1月4日 Specifications: The capacity of a laboratory ball mill is 05 to 20 kg per batch and can achieve particle sizes down to 45 microns Screening Equipment; Vibrating Screens: Understanding magnesite and its beneficiation process is crucial for industries that rely on this valuable mineral By following the steps outlined in this blog Lab Equipment for Magnesite Beneficiation Testing JXSC 2023年4月30日 According to the ratio of cylinder length (L) to diameter (D), the ball mill can be divided into short cylinder ball mill, L/D ≤ 1; long barrel ball mill, L/D ≥ 1–15 or even 2–3; and tube mill, L/D ≥ 3–5 According to the cylinder shape of the ball mill, it can be divided into cylindrical ball mill and cone ball millBall Mill SpringerLinkBased on the MPT TITAN™ design, the Mills are girth gear dual pinion driven with selfaligned flanged motors, running on hydrodynamic oil lubricated bearings The TITAN design enables you to run full process load 40% Ball charge at 80% critical speed – Max grinding power for every shell size Standard Mill Types Available: Overflow Ball Ball Mills MechProTech MPT2019年8月14日 When removing the ball mill liner, the personnel should pay attention to safety, pay attention to the position, and avoid being injured by the ball mill liner 5 The size of the ball mill is large, and it is necessary to carry out lifting work The Ultimate Guide to Ball Mills MiningpediaGebr Pfeiffer Spezialist für

.jpg)

Ball Mills 911Metallurgist

2017年2月13日 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment