Raymond Mill For Mineral Processing Plants

Raymond Mill Cronus Machinery

Raymond mill is the core equipment for nonmetallic mineral powder processing with its high efficiency, energy saving and environmental protection Different models are suitable for different production requirements Choose the 2024年12月27日 In summary, the Raymond mill is a crucial piece of equipment in the mineral processing industry, particularly for grinding a variety of minerals into fine powders Its working Working Principle of Raymond Mill and the Application of Raymond mill2024年8月14日 Raymond mill is widely used in the grinding and processing of mineral products in the fields of metallurgy, building materials, chemical industry, mining, etc It is suitable for processing various nonflammable and explosive Raymond Mill Zhengzhou Shibo Machinery 2025年1月6日 Raymond Mill is a widely used grinding machine in industries such as mining, construction, and metallurgy Renowned for its efficiency and durability, this machine plays a Understanding Raymond Mill: Its Working Principle, 2023年6月12日 (1) Raymond mill has compact structure, small space occupation, strong completeness, and an independent production system from block materials to finished powder (2) The finished powder has a uniform 6 Aspects For You to Understand Raymond Mill5 天之前 A Raymond mill, also known as a Raymond roller mill, is a type of grinding mill used to pulverize various materials into fine powder It is widely used in industries such as mining, construction, chemical, and metallurgy for Raymond Mill TAYMACHINERY

.jpg)

Raymond millBaichy Machinery

2025年4月2日 Raymond mill is a highefficiency closedcircuit fine powder grinding mill plant for nonmetallic minerals The finished particle size is relatively fine and uniform, and could well meet the material requirements of various fields2025年3月25日 Raymond grinding mill is suitable for processing various nonflammable and nonexplosive mineral materials with Moh's hardness less than 93 and humidity less than 6%, Raymond mill clirikchina2025年2月28日 Raymond mill, widely used in minerals grinding process of metallurgy, building materials, chemicals, mining and other fields, is suitable for processing various nonflammable Raymond millGrinding mill machine, mineral mill, raymond mill 2024年6月4日 Raw Materials Suitable for Raymond Mill Processing Raymond mills excel in grinding nonflammable and nonexplosive materials with a Moh’s hardness below 7 and moisture content below 6%, making them ideal for Raymond Mill CMPP carbonmanagement 2017年7月1日 Raymond 5057 Rollers Air Classifier Whizzer 4 Roller Arm Assembly Mineral Grinding Plant Raymond 5057 Bull Ring Call Send Email 3 Roller Master Mills; Mineral Processing Plants; 4 Roller Mill Spare Parts; View More Our Company Who We Are ; Our Products ;Master Pulverisers (India) Private Limited Manufacturer of 3 CR1500 Raymond Mill: Unlimited vitality, igniting new hope for industrial grinding Raymond mill is the core equipment for nonmetallic mineral powder processing with its high efficiency, energy saving and environmental protection Different Raymond millSuperfine grinding millUltrafine

.jpg)

Raymond mill CMPP carbonmanagementpowerplants

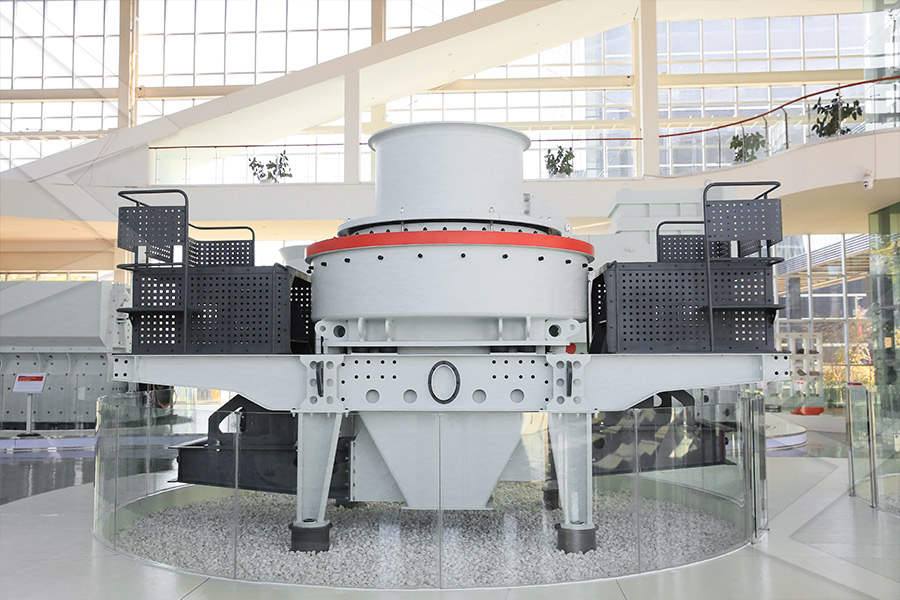

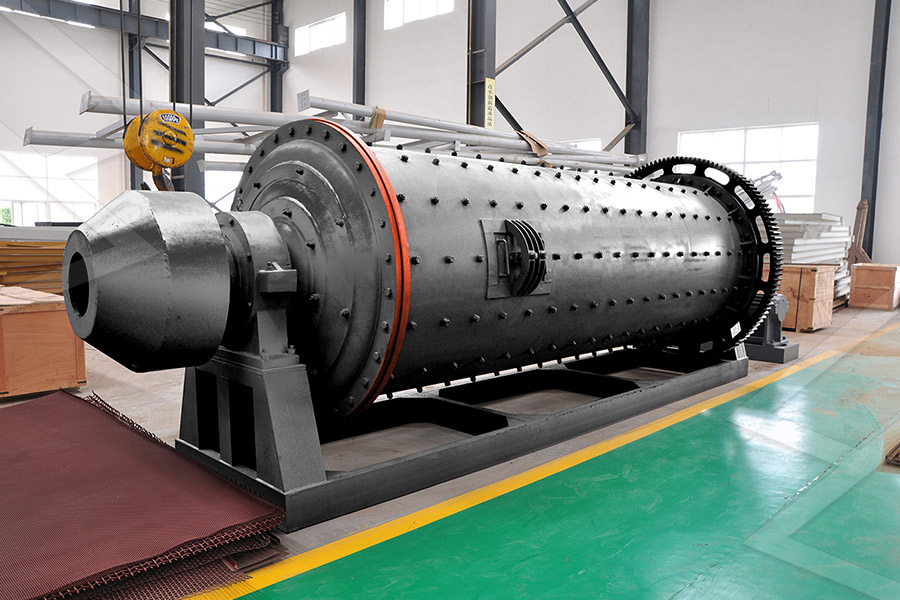

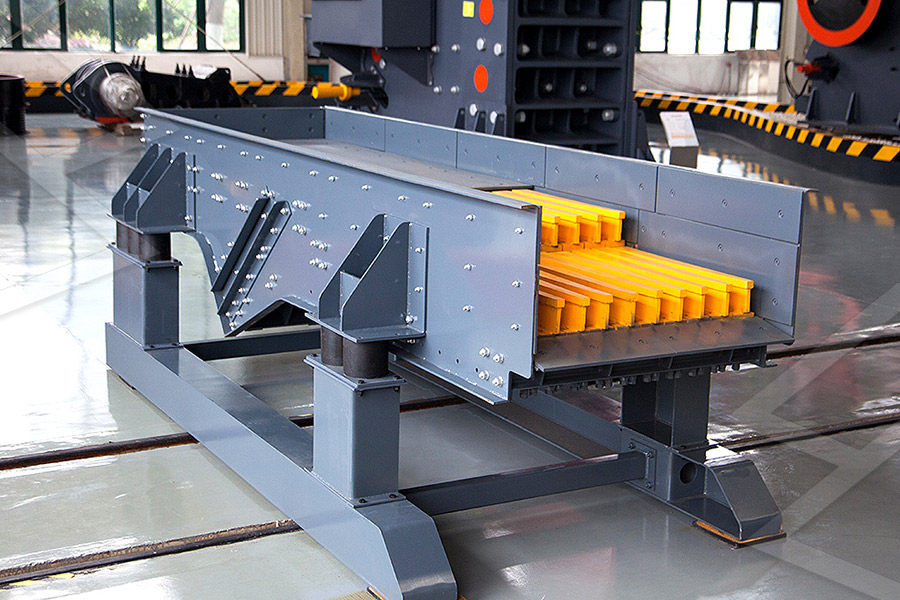

The mills’ high throughput rates and reliability serve the highvolume demands of industrial mineral processing, ensuring a steady supply of finely ground mineral fertilizers to the market The Unique Features of Raymond Mills Raymond mills feature an advanced pulverizing process, which is engineered for high precision and minimal loss The The size of the discharge of the gridtype ball mill is generally 02~03mm, which is often used in the one stage of grinding in the mineral processing plant (2) Overflow Ball Mill The structure of the overflow ball mill is similar to the grid ball mill But there are differences between overflow ball mill and grid ball millEverything You Need to Know about Mineral Grinding 2018年7月19日 types of mineral processing industries Our negative pressure conditions, minimizing mill maintenance and plant housekeeping while maximizing the Raymond roller mills are available with grinding ring diameters ranging from 30 inches to 120 inches (760 to 3050 mm) These sizes are capable of producing a wide range of product fineness RAYMOND® ROLLER MILLS Thomasnet4 天之前 Baichy Machinery is a professional mining machinery manufacturer for stone crusher, mobile stone crushing plant, Raymond mill, ball mill, and mineral processing equipment It covers a total area of 200,000 m2 workshop and office building There are more than 200 sets of various large and mediumsized metal processing lathe, riveting machine, welding equipment and Henan Baichy Machinery Equipment Co,Ltd2025年1月6日 Raymond Mill is a widely used grinding machine in industries such as mining, construction, and metallurgy Renowned for its efficiency and durability, this machine plays a critical role in mineral processing and production linesUnderstanding Raymond Mill: Its Working Principle, 2024年9月24日 Baichy Machinery is a factory supplier of mining machinery, mainly focusing onstone crushers, powder grinding mills, and mineral beneficiation plantsWe can offer you a free design and completed solutions according to your project Baichy Heavy Industry has grown into a hightech mining equipment comprehensive enterprise, integrating RD, manufacturing, sales, Raymond Mill History, Working Principles Applications

.jpg)

Copper Ore Processing Plants, Flow And Equipment

2025年4月2日 Copper industrial minerals include: natural copper, chalcopyrite, chalcocite, tetrahedrite, azurite, malachite, etc Chalcopyrite (a compound of copper, sulfur, and iron) is mined mainly, followed by chalcocite and bornite If copper ore wants to be fully utilized, it must be processed by flotation Flotation separation is an important copper ore beneficiation process in 2024年6月4日 Raw Materials Suitable for Raymond Mill Processing Raymond mills excel in grinding nonflammable and nonexplosive materials with a Moh’s hardness below 7 and moisture content below 6%, making them ideal for processing a wide range of mineral fertilizers Examples of raw materials include phosphate rock, potash, dolomite, and gypsum These Raymond Mill CMPP carbonmanagementpowerplantsIndustrial Raymond mill, also known as YGM Raymond mill and Raymond machine, is a high efficiency pulverizing mill that replaces ball mills to process ore powder smooth transmission, high wear resistance and convenient YGM Industrial Raymond MillRaymond mill is the core equipment for nonmetallic mineral powder processing with its high efficiency, energy saving and environmental protection Different models are suitable for different production requirements CRRM Pendulum Raymond Mill Cronus Machinery2025年4月3日 The Raymond mill, also called Raymond roller mill, combines grinding, classifying, and if necessary, drying, in one machine to produce precisely sized powders to meet exact production specificationsIt is an efficient fine grinding machine for largescale powder production Applied materials: various nonflammable and explosive minerals such as gypsum, Raymond Mill epicpowderBrief Introduction of CLRM series Raymond mill CLRM series Raymond mill is suitable for processing various nonflammable and nonexplosive mineral materials with Mohs hardness less than 6 and humidity less than 6% It is widely used in metallurgy, construction, chemical industry, mining, highway construction and other fieldsCLRM series Raymond mill SBM Ultrafine Powder Technology

Modular Plants: Gold Processing

2023年8月29日 SGS Bateman modular plants are self contained or are integrated into conventional plants They are used for prospecting, exploration, research, pilot plant and mineral processing on land or sea The process design is robust and makes use of the best available components from reputable suppliers that support their products worldwide2025年2月28日 Raymond mill, widely used in minerals grinding process of metallurgy, building materials, chemicals, mining and other fields Home Product Case About Liming Raymond mill, widely used in minerals grinding process of metallurgy, building materials, chemicals, mining and other fields, is suitable for processing various nonflammable and non Raymond mill, raymond grinding mill, MTW European Type Trapezium Mill4 天之前 The mineral processing equipment industry is a specialized sector dealing with the manufacture and distribution of machines facilitating the extraction, treatment, and handling of mineral substances These companies produce a varied range of equipment, from crushing and grinding machinery to extraction units and mineral processing plantsTop 23 Companies in Mineral Processing Equipment Industry 2021年8月17日 Maxing Feeding Size: 40 mm Ouput Size: 06130033 micron (40400 mesh) Capacity: 125 t/h D97 325 mesh 2μm 10% Raymond Roller Grinding Mill Machine also named Raymond Mill, Raymond Roller Mill, 3R/4R/5R/6R Roller Mill and Raymond Mill Machine It is widely applied in ore materials grinding Raymond mill is the key equipment of powder Raymond Roller Grinding Mill MachineThe comparison between the new ultrafine Raymond mill and the traditional Raymond mill is a widely used milling equipment Raymond Mill is a widely used grinding equipment for mines, cement plants and chemical plants It is one of the important equipment for deep processing of nonmetallic minerals The advantages of the new Raymond millDisadvantages of Traditional Raymond Mill and Advantages of New Raymond 2025年4月2日 It has high processing capacity, high separation efficiency and low energy consumption petroleum coke, quartz, iron ore, phosphate rock, gypsum, graphite and other noninflammable and nonexplosive mineral Raymond Mill: Working Principle Parts

.jpg)

Limestone crushing plant, limestone grinding mill

2023年1月19日 The Recommend Machine is PE Jaw Crusher, PFW Impact Crusher, Raymond Mill, MTM Medium Speed Trapezium Mill, MTW Continental Trapezoid Mill are the best choices for limestone powder production,because its' Product fineness can be 2025年4月3日 The Raymond Mill is a grinding machine, suitable for the preparation of various kinds of mineral powder and coal powder preparation SBM has launched three upgrade series of Raymond Mills, MB5X Pendulum Roller Raymond Mill History, Working Principle2022年7月5日 The three minerals, spodumene, petalite, and lepidolite, can be used for various purposes after beneficiation and concentrationThe cutoff grade and industrial grade of lithium deposits are divided into manual beneficiation and machine beneficiation, and the grade indicators are determined respectivelyThe division between manual and machine Lithium Processing Plant JXSC Machine1 天前 Rare metal ore processing mainly including lithium, tantalumniobium minerals separation plants are enriched and purified through gravity separation, flotation, magnetic separation and other process to increase its concentration for further extraction JXSC uses cuttingedge technology production equipment and optimized mineral processing flow to greatly improve the Mineral Processing Plant Beneficiation Solutions2025年4月4日 Mineral Processing Gypsum processing can be divided into three basic steps: (1) rock preparation, (2) calcining, and (3) formulating and manufacturing the most commonly used mill for reducing gypsum to a fine powder has been the Raymond mill Raymond mills consist of a vertically rotating shaft with articulated arms ending with steel Infrastructure and Construction Materials Guide — Gypsum Minerals Raymond Mill has a strong performance become a complete set with a production system independentlyAll important parts of Raymond Mill are made of high quality steel, and all wearresistant parts are made of highperformance wearresistant materials Zinc Processing Plant More >>> NonMetal Mineral Barite Mineral Processing Dolomite Mining Raymond Mill, Raymond Mill Plant, raymond grinding mill

Raymond Grinding Mill JXSC Mineral

2025年3月27日 The main parts of a raymond grinding mill plant are a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc, Mineral Processing Plant Mineral Processing Consulting Services Other Capacity(T/H) 010 T/H 1050 T/H 50100 T/H 100300 T/H 2023年1月19日 Ball Mill for kaolin is the common grinding mill in kaolin production line, it is used for coarse grinding, the finished size is 007404 mm Raymond Mill is the traditonal Grinding mill and porpular around the world It finish particles have a good uniformity of finess, with passing screen rate as high as 98%Kaolin crushing and grinding process equipment, kaolin ball mill2021年10月19日 Raymond Mill Working Principle The Raymond Mill is mainly composed of a host, an analytical machine, a fan, a finishedproduct cyclone collector, a finepowder cyclone collector and air ducts Of them, the host is made up of a frame, an inlet volute, a shovel blade, grinding rollers, a grinding ring and a shellHow Does a Raymond Mill Work? Zenith Crusher2024年6月4日 Raw Materials Suitable for Raymond Mill Processing Raymond mills excel in grinding nonflammable and nonexplosive materials with a Moh’s hardness below 7 and moisture content below 6%, making them ideal for Raymond Mill CMPP carbonmanagement 2017年7月1日 Raymond 5057 Rollers Air Classifier Whizzer 4 Roller Arm Assembly Mineral Grinding Plant Raymond 5057 Bull Ring Call Send Email 3 Roller Master Mills; Mineral Processing Plants; 4 Roller Mill Spare Parts; View More Our Company Who We Are ; Our Products ;Master Pulverisers (India) Private Limited Manufacturer of 3 CR1500 Raymond Mill: Unlimited vitality, igniting new hope for industrial grinding Raymond mill is the core equipment for nonmetallic mineral powder processing with its high efficiency, energy saving and environmental protection Different Raymond millSuperfine grinding millUltrafine

.jpg)

Raymond mill CMPP carbonmanagementpowerplants

The mills’ high throughput rates and reliability serve the highvolume demands of industrial mineral processing, ensuring a steady supply of finely ground mineral fertilizers to the market The Unique Features of Raymond Mills Raymond mills feature an advanced pulverizing process, which is engineered for high precision and minimal loss The The size of the discharge of the gridtype ball mill is generally 02~03mm, which is often used in the one stage of grinding in the mineral processing plant (2) Overflow Ball Mill The structure of the overflow ball mill is similar to the grid ball mill But there are differences between overflow ball mill and grid ball millEverything You Need to Know about Mineral Grinding 2018年7月19日 types of mineral processing industries Our negative pressure conditions, minimizing mill maintenance and plant housekeeping while maximizing the Raymond roller mills are available with grinding ring diameters ranging from 30 inches to 120 inches (760 to 3050 mm) These sizes are capable of producing a wide range of product fineness RAYMOND® ROLLER MILLS Thomasnet4 天之前 Baichy Machinery is a professional mining machinery manufacturer for stone crusher, mobile stone crushing plant, Raymond mill, ball mill, and mineral processing equipment It covers a total area of 200,000 m2 workshop and office building There are more than 200 sets of various large and mediumsized metal processing lathe, riveting machine, welding equipment and Henan Baichy Machinery Equipment Co,Ltd2025年1月6日 Raymond Mill is a widely used grinding machine in industries such as mining, construction, and metallurgy Renowned for its efficiency and durability, this machine plays a critical role in mineral processing and production linesUnderstanding Raymond Mill: Its Working Principle, 2024年9月24日 Baichy Machinery is a factory supplier of mining machinery, mainly focusing onstone crushers, powder grinding mills, and mineral beneficiation plantsWe can offer you a free design and completed solutions according to your project Baichy Heavy Industry has grown into a hightech mining equipment comprehensive enterprise, integrating RD, manufacturing, sales, Raymond Mill History, Working Principles Applications

Copper Ore Processing Plants, Flow And Equipment

2025年4月2日 Copper industrial minerals include: natural copper, chalcopyrite, chalcocite, tetrahedrite, azurite, malachite, etc Chalcopyrite (a compound of copper, sulfur, and iron) is mined mainly, followed by chalcocite and bornite If copper ore wants to be fully utilized, it must be processed by flotation Flotation separation is an important copper ore beneficiation process in